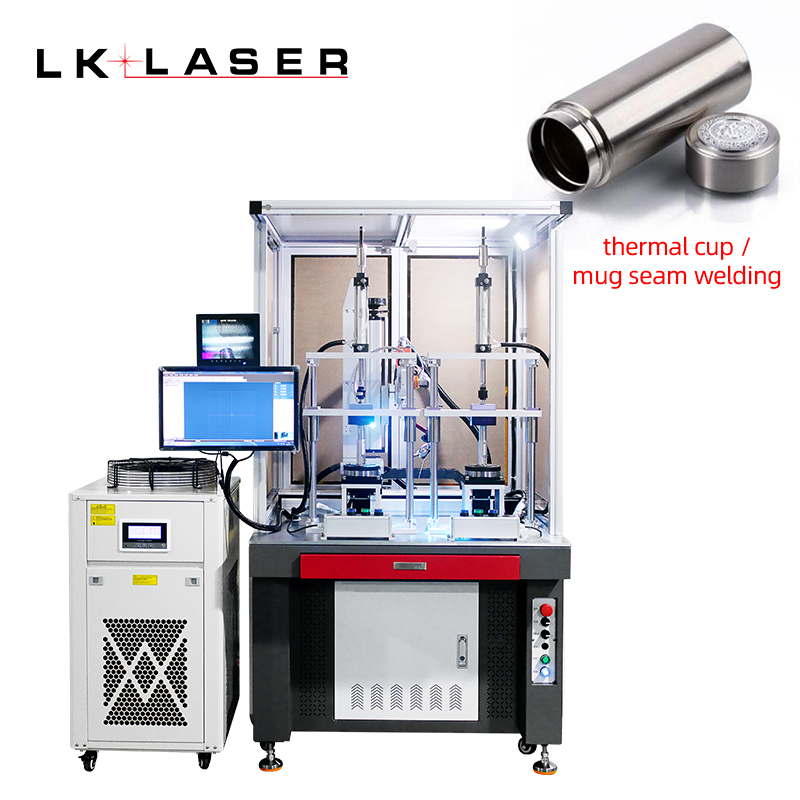

Model :LK-LWF

Power options : 150W/300W

Application Materials : such as aluminum, stainless steel, carbon steel.....

Product Advantages : Reliable solutions for producing precision welding micro dental, medical components, gear, watch strap, battery pack, sensor, metal bellows

24 Month maintenance

Fast delivery

24 Hour treatment

Feature :

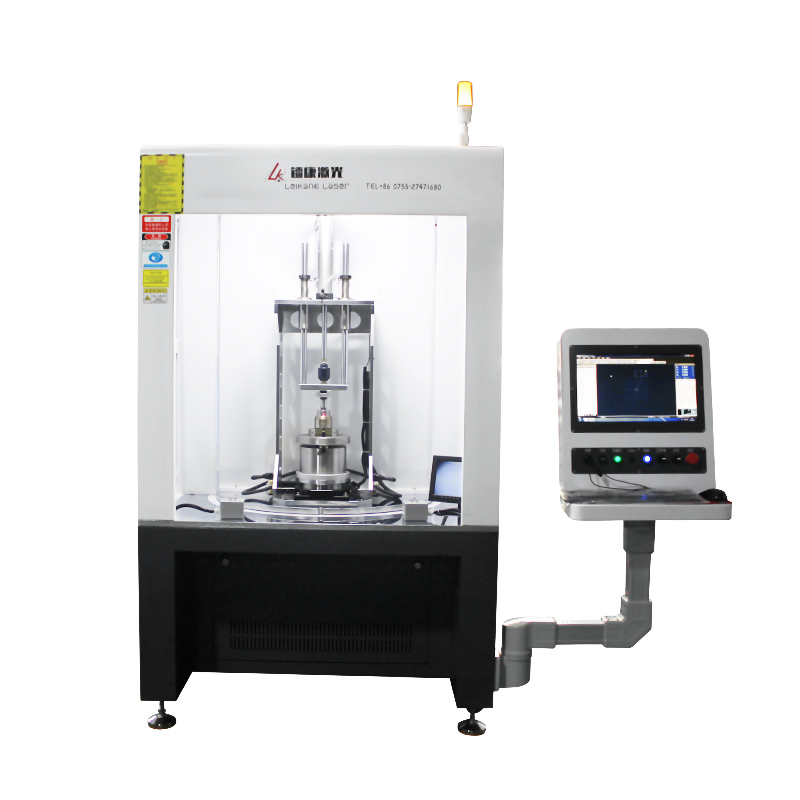

The 8-axis system supports smooth welding path planning, avoiding weld defects caused by sudden direction changes, and ensuring uniform weld width and consistent penetration depth.

machine achieves multi-dimensional linkage control. It can complete complex welding router

Integrated with advanced CNC control system and laser power adjustment technology, the machine can automatically match welding parameters (laser power, welding speed, pulse frequency) according to different material types (stainless steel, aluminum alloy, copper, titanium alloy) and workpiece thicknesses.

It is equipped with a real-time monitoring module (CCD visual ), which can dynamically check the weld position

supporting parameter preset, process storage (up to 80 sets of process files), and fault diagnosis prompts, which is convenient for operators to get started quickly without professional skills.

|

Laser power |

150W/ 300W |

|

Laser Type |

QCW Fiber laser |

|

Focus mode |

Manual /automatic |

|

Axis |

8 axis |

|

Welding head |

LK Laser |

|

Cooling system |

Air Cooling |

|

Welding speed |

20m/min |

|

Repeatability |

+-0.03mm |

|

Welding accuracy |

+-0.05mm |

|

Welding software |

Caddsp |

|

Welding control card |

LK LASER |

|

Machine packing size |

1320*1320*1920mm |

|

Machine net weight |

420KGS |

|

Machine gross weight |

450KGS |

|

1 Fixture |

5 Protective lens |

|

1 Protective goggles |

1 Power cable |

|

1 data cable |

1 tool kit |

|

1 U disk |

Machine |